The Transparent Guardian: Rolul filmului alb BOPS în soluțiile moderne de ambalare

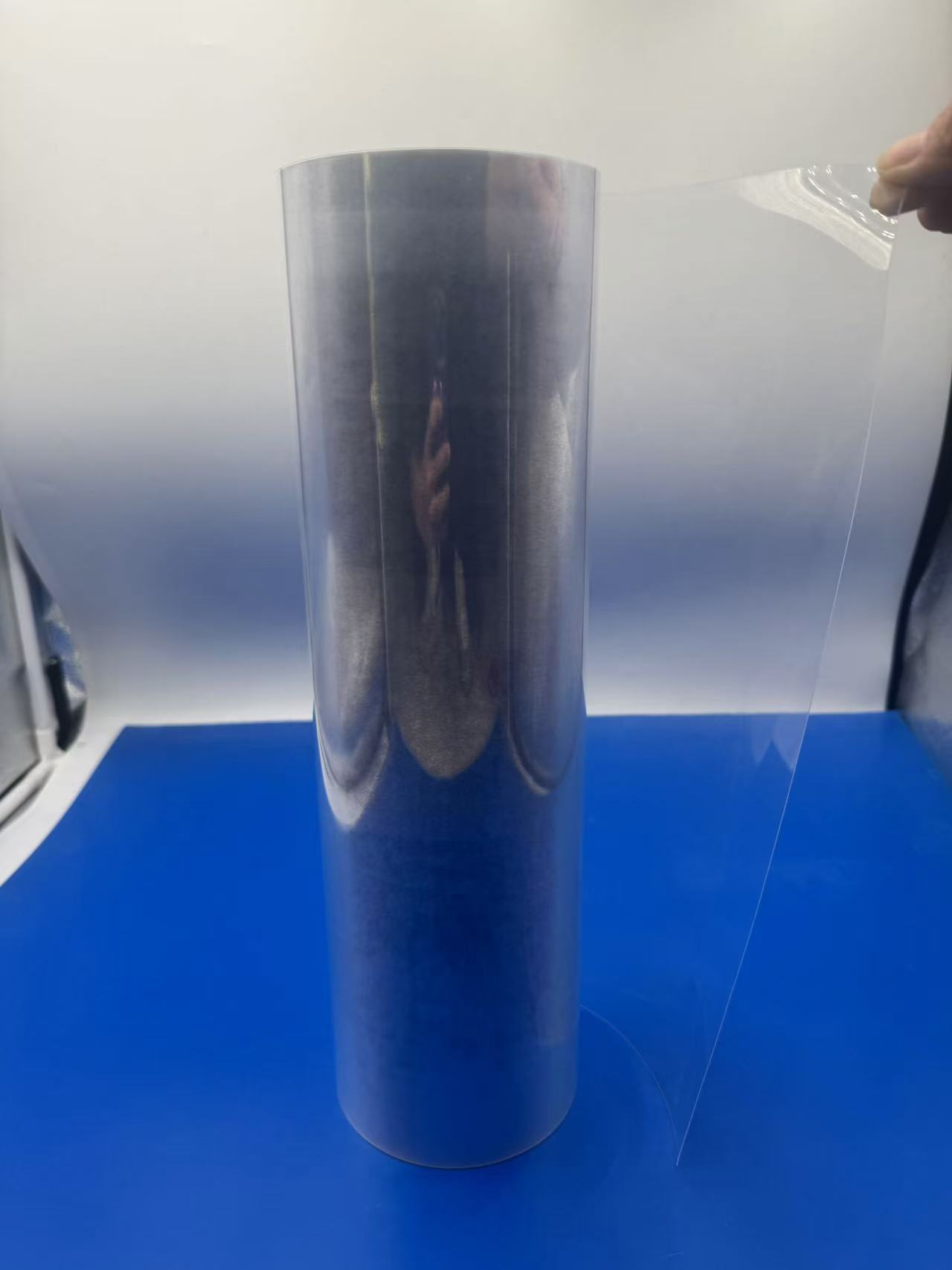

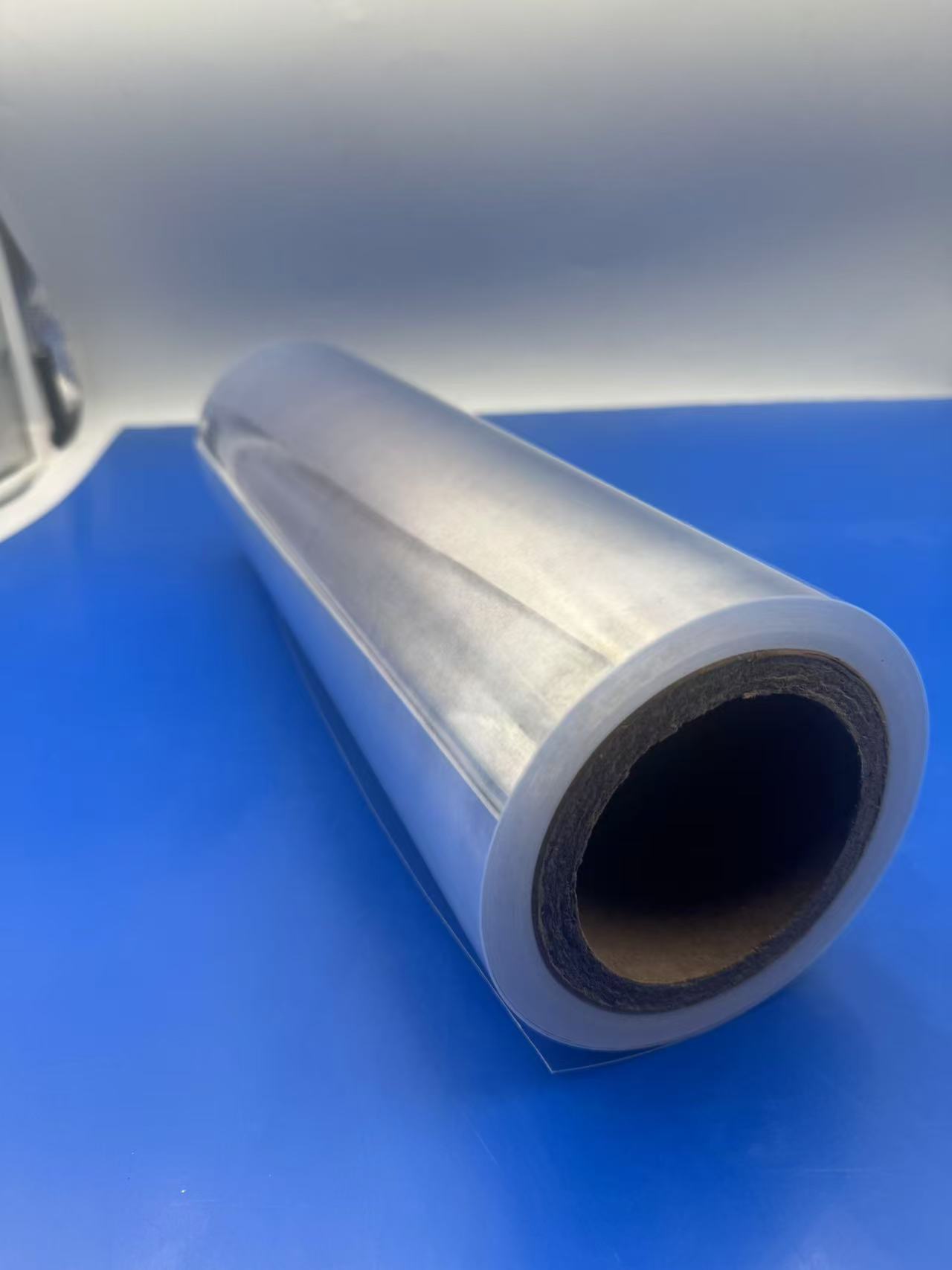

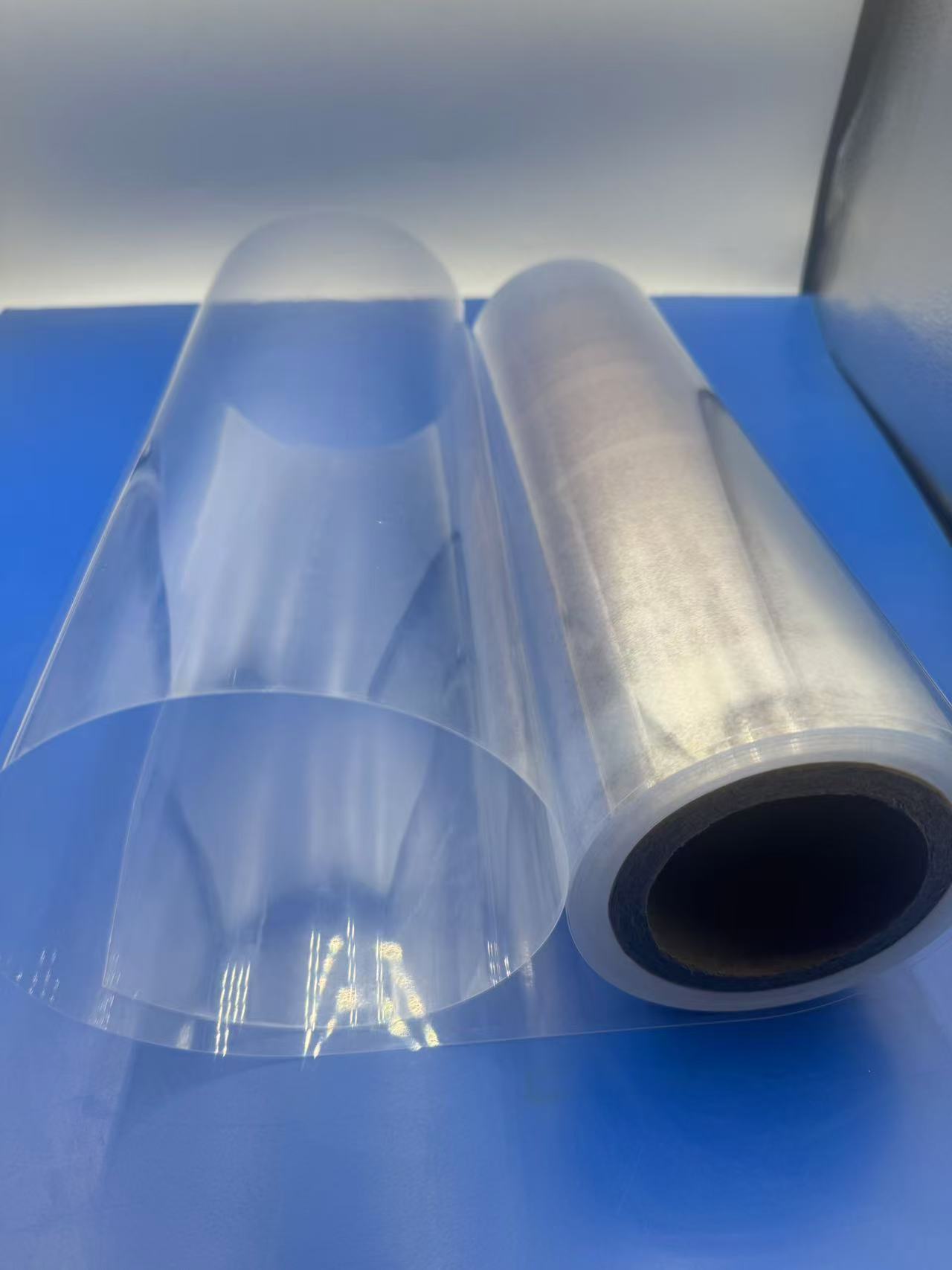

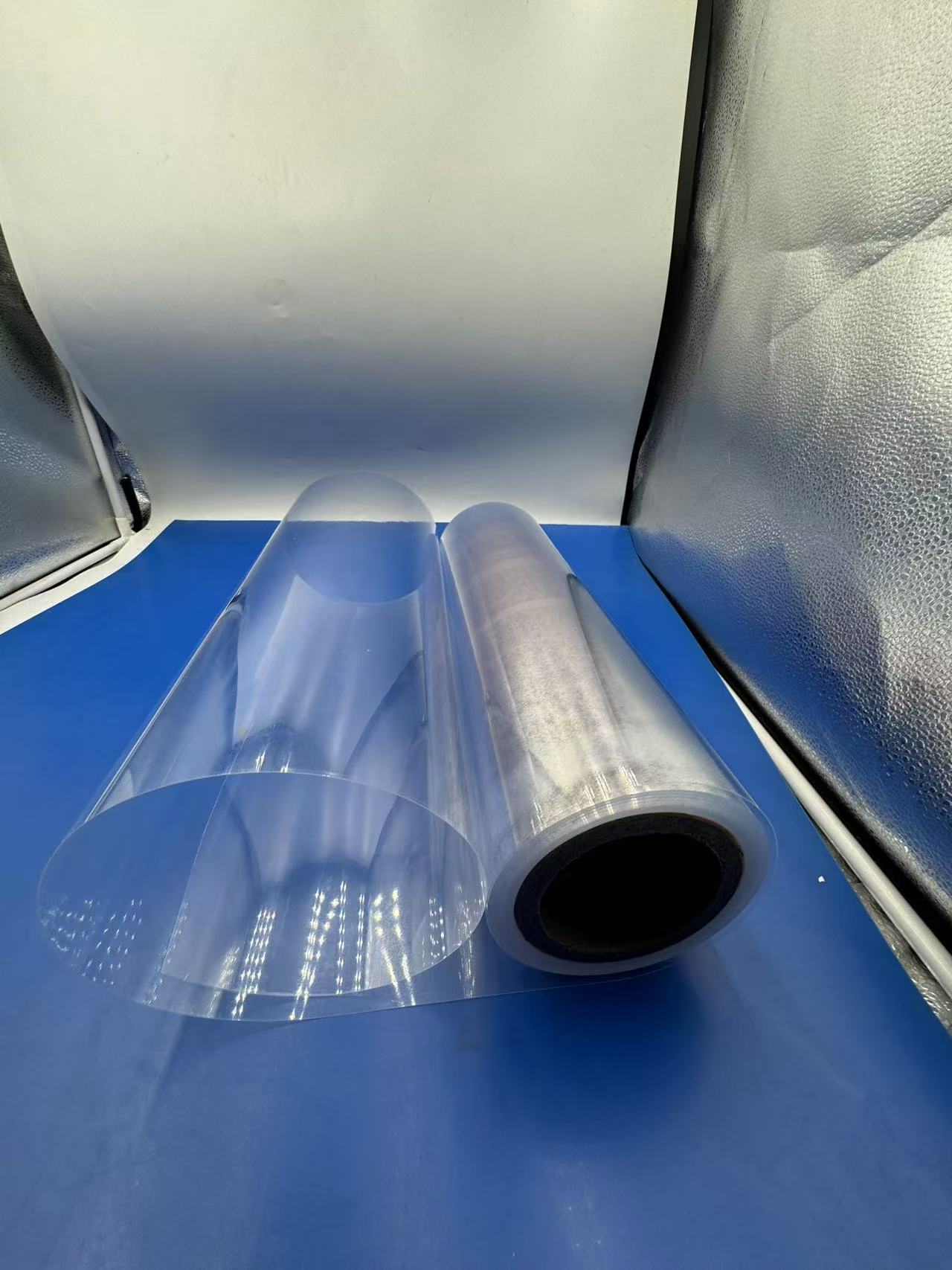

Material: folie blister BOPS

Grosime 0,25 mm/personalizare

Dimensiune: 100mm/Personalizare

GRAD: Film alimentar

culoare: transparent/alb/ personalizare

locatie: China

utilizare: pentru tava pentru alimente, tava pentru legume, cutie de afișare anti-aburire

- TOPLEADER

- China

- 15 ZILE LUCRĂTOARE

- 5000T/M

- informație

- video

- descărcare

Introduction

In the ever-evolving world of packaging, materials that offer both functionality and aesthetic appeal are highly sought after.

White Biaxially Oriented Polystyrene (BOPS) film stands out as a versatile material, especially in the realm of thermoforming, where its properties like transparency, strength, and moisture resistance are leveraged across various industries. This article explores the characteristics of white BOPS film and its applications in food packaging, fresh produce packaging, anti-fog packaging, and pharmaceutical packaging, providing a detailed look at how this material shapes our daily consumption.

Understanding White BOPS

BOPS or Biaxially Oriented Polystyrene is a type of plastic film that undergoes stretching in two directions to enhance its physical properties. Here’s why white BOPS is particularly noteworthy:

Clarity and Aesthetics: White BOPS provides crystal-clear visibility, showcasing the product inside while adding a clean, appealing aesthetic with its white color, which is often associated with purity or freshness.

Moisture Resistance: Despite its high clarity, BOPS offers good resistance to moisture, which is crucial for packaging where product freshness needs to be maintained.

Thermoformability: BOPS can be easily shaped into various forms through thermoforming, offering flexibility in packaging design.

Applications in Food Packaging

Food Packaging benefits immensely from BOPS due to its combination of visual appeal and protective qualities:

Snack Foods: BOPS is used for packaging chips, candies, and biscuits, where the clear film allows consumers to see the product before purchase, enhancing sales through visual appeal.

Bakery Products: For pastries, cakes, and bread, BOPS provides a barrier against environmental elements while maintaining product freshness. The white variant adds an extra layer of perceived cleanliness.

Meat and Dairy: The film’s rigidity ensures that packages maintain their shape, even when containing heavier products like cheese or meat slices, while its clarity allows for product inspection.

Visible Fresh Produce Packaging

When it comes to fresh produce packaging, BOPS's transparency is a game-changer:

Vegetable and Fruit Trays: BOPS is ideal for packaging fresh produce like salads, berries, or cherry tomatoes where the product must be visible to attract consumers. Its resistance to punctures also protects delicate items during transit.

Custom Shapes: The ability to thermoform BOPS into various shapes supports the packaging of oddly shaped vegetables or fruits, ensuring minimal waste and maximum appeal.

Anti-fog Packaging

Anti-fog BOPS is specifically engineered for environments where condensation could otherwise cloud the viewing window:

Refrigerated Display: In supermarkets, where products are displayed in chilled environments, anti-fog BOPS ensures that condensation does not obscure the product, maintaining its shelf appeal.

Prepared Foods: For ready-to-eat meals or salads, this feature keeps the packaging clear, allowing consumers to see the product's freshness and quality.

Pharmaceutical Packaging

In pharmaceutical packaging, BOPS offers both protection and visibility:

Blister Packs: BOPS’s rigidity and clarity make it perfect for blister packaging of tablets or capsules, allowing for easy identification and inspection. The white color can also provide a backdrop that enhances product visibility.

Sterile Packaging: For items that need to remain sterile until opened, BOPS provides a barrier against contaminants while allowing for visual confirmation of seal integrity.

Medical Devices: Small medical tools or single-use devices are often packaged in BOPS due to its ability to maintain sterility and withstand the rigors of shipping and handling.

Thermoforming with BOPS

The process of thermoforming with white BOPS involves:

Heating: The film is heated to soften it.

Molding: It's then shaped into the desired form using a mold.

Cooling: The formed shape is cooled to set.

This process allows for the creation of custom packaging solutions that fit the product perfectly, reducing material use and enhancing presentation.

Challenges and Innovations

Environmental Impact: While BOPS provides many benefits, its environmental footprint, particularly recyclability, remains a challenge. Innovations include exploring more biodegradable or recyclable versions of BOPS.

Cost: Higher production costs due to the orientation process can be a barrier, though the benefits often outweigh these costs in critical applications.

Advances in Clarity: Ongoing research aims at improving the clarity and anti-fog properties even further, making BOPS even more suitable for premium packaging solutions.

Conclusion

White BOPS film, with its unique combination of clarity, strength, and moisture resistance, plays a vital role in modern packaging. From food to pharmaceuticals, its applications are wide-ranging, showcasing not only the product but also ensuring its quality from production to consumption. As industries continue to push for sustainability and innovation, BOPS is poised to adapt, potentially revolutionizing packaging further with advancements in material science and manufacturing processes. This material not only preserves but enhances the consumer experience, making it an indispensable part of the packaging ecosystem.

În termen de 15-20 de zile de la primirea plății...more