Dezvăluirea diferitelor utilizări ale filmului CPP Introducere în filmul CPP

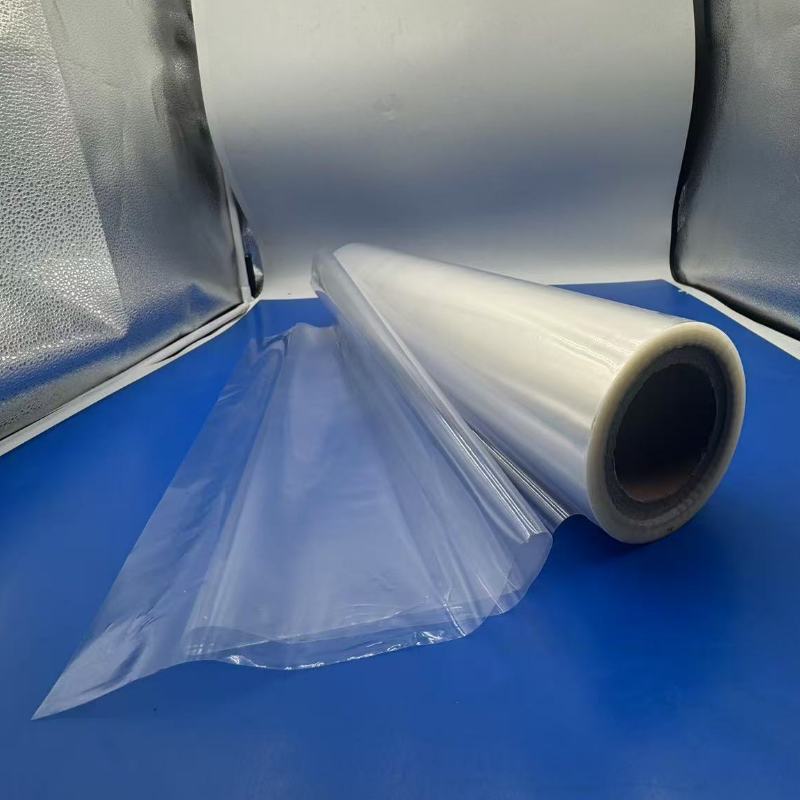

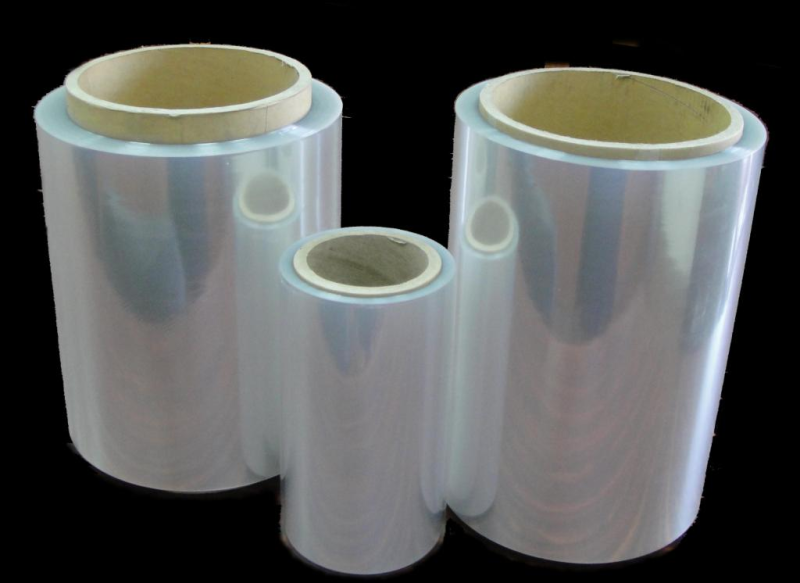

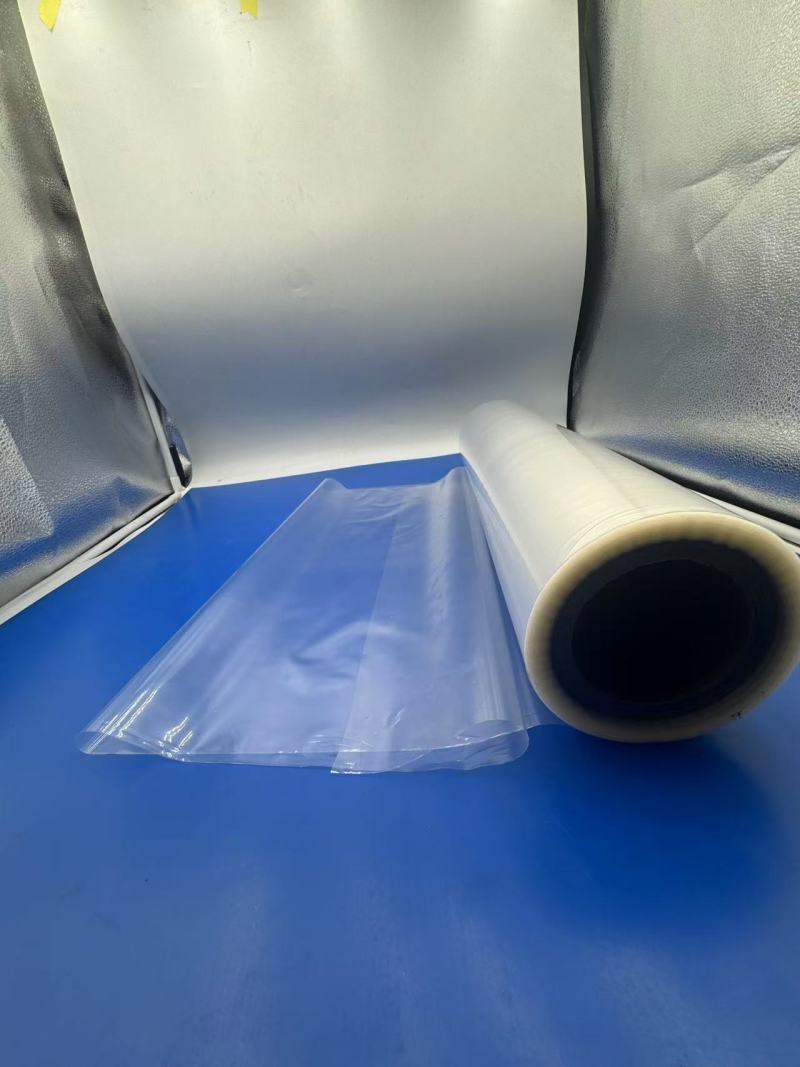

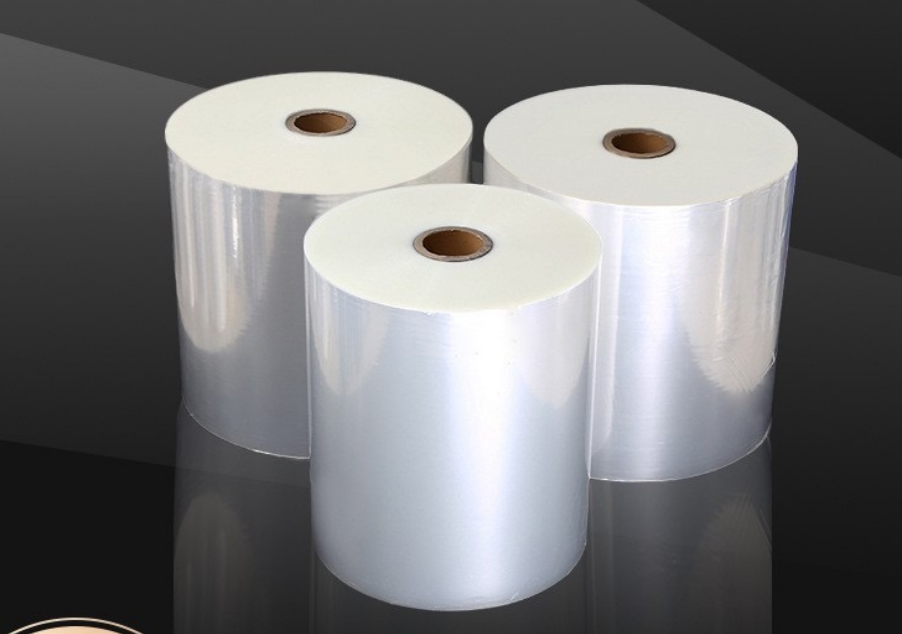

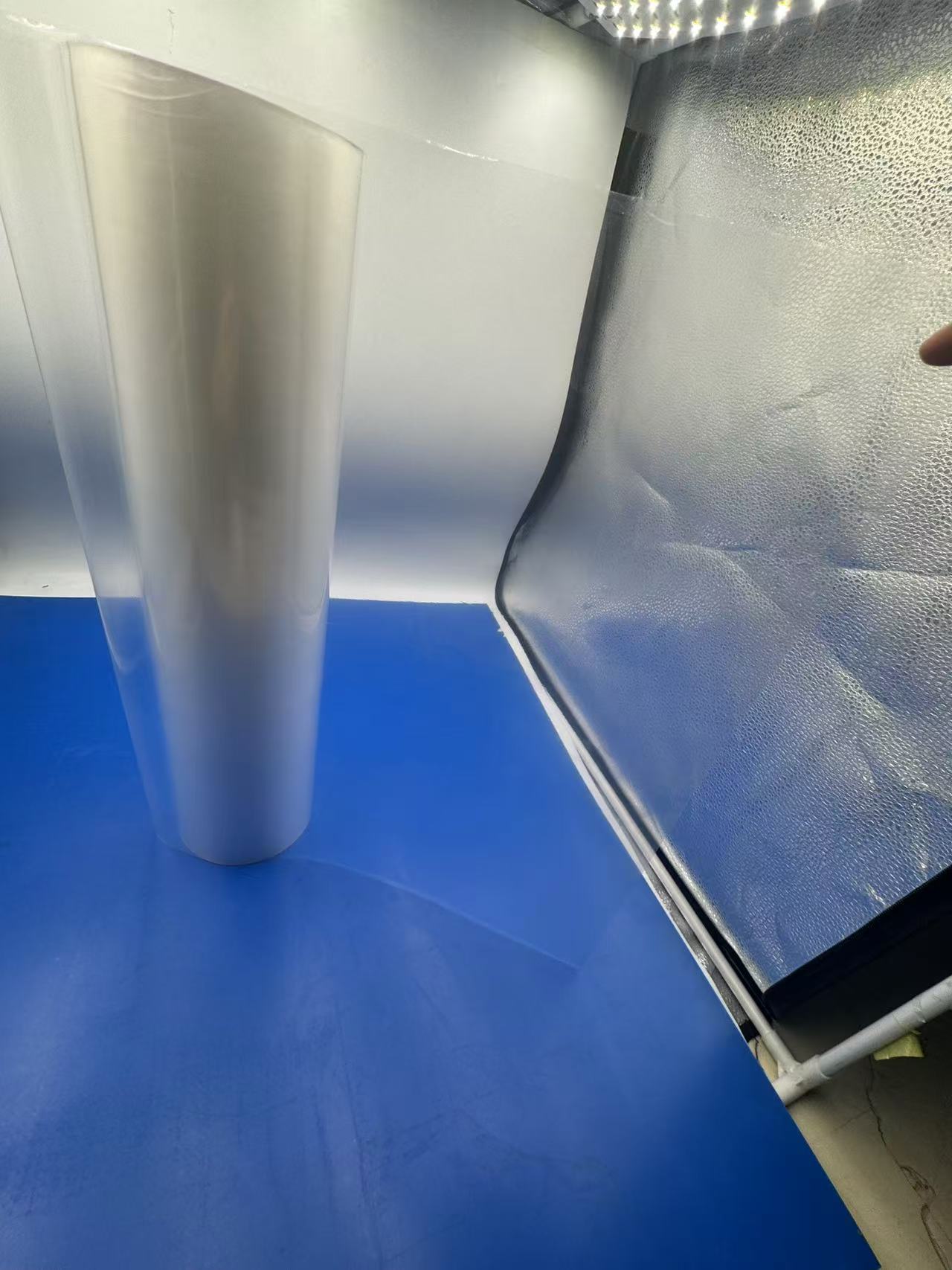

Material: rola de film cpp

Grosime 0,012 mm/personalizare

Dimensiune: A4/Personalizare

GRAD: Film alimentar

culoare: alb/ceață/mat/personalizare clară

locatie: China

utilizare: pentru protecția alimentelor, cutie de termoetanșare pentru alimente, laminare

- TOPLEADER

- China

- 15 ZILE LUCRĂTOARE

- 5000T/M

- informație

- video

- descărcare

Unveiling the Various Utilizations of CPP Film Introduction to CPP Film

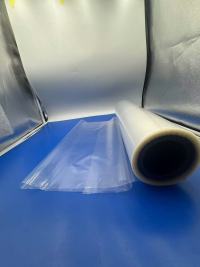

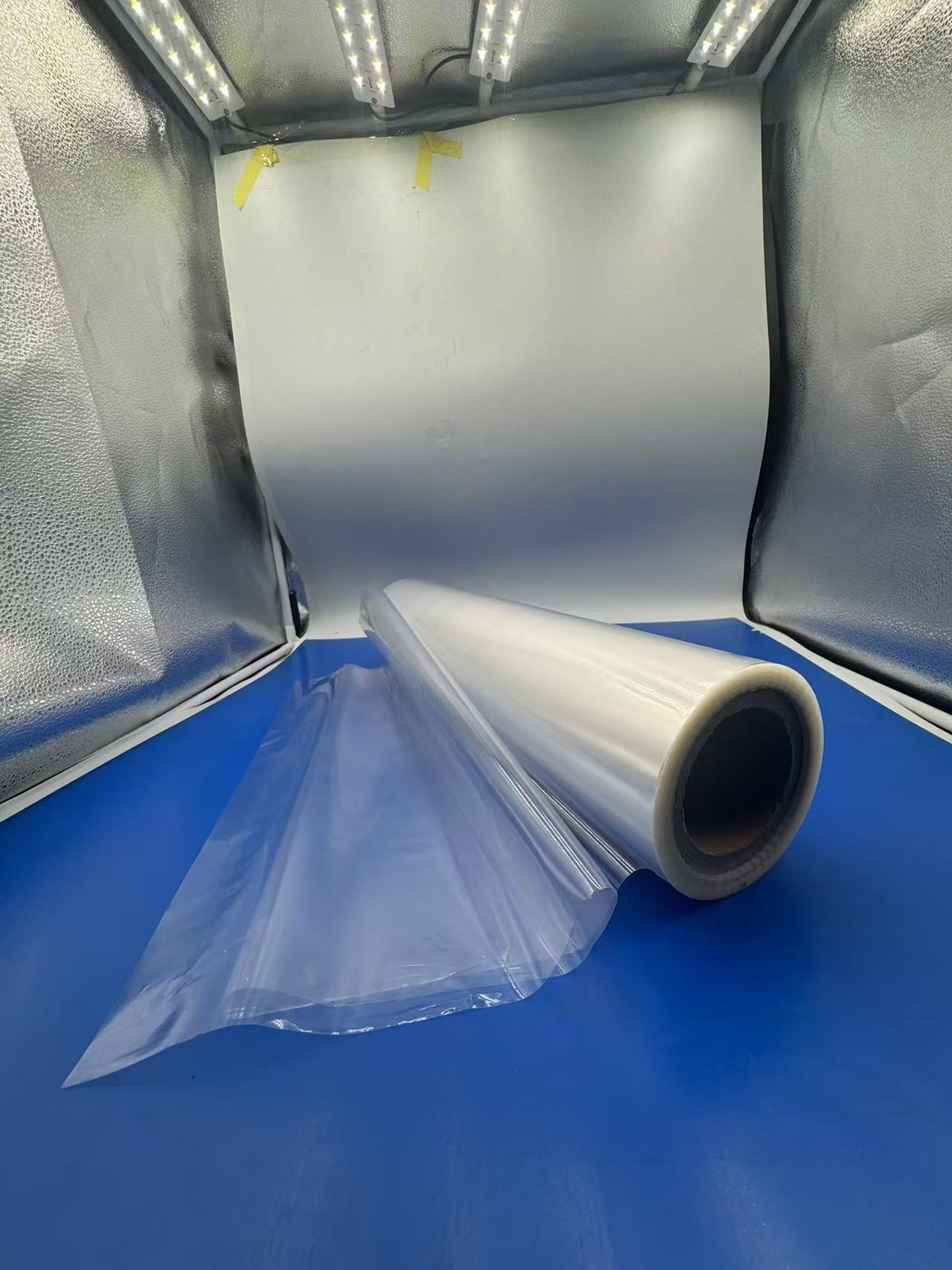

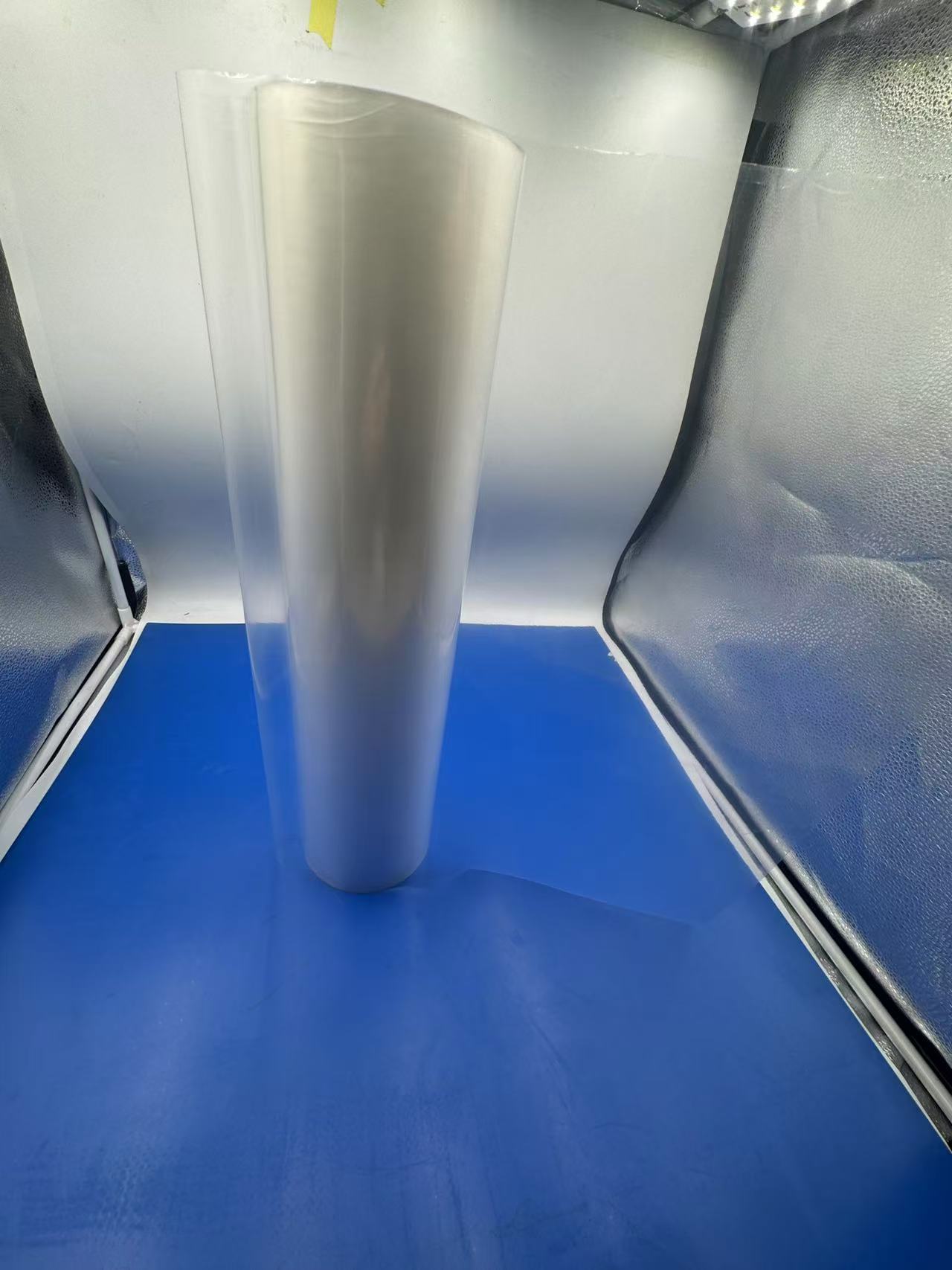

CPP is one of the versatile packaging films because of its superior transparency, flexibility, and good sealing characteristics. CPP film produced by cast extrusion process has several advantages over the other polypropylene films, including BOPP, due to the unoriented structure. This review discusses uses of CPP film in many applications starting from sealing packaging, bag making to other novel usages in many sectors.

Sealing Packaging with CPP Film

Among all the applications, the foremost is Sealing, whereby CPP film leads the race with the following intrinsic properties:

Heat Sealing: CPP film, because of its good heat-sealing property, is suitable for applications that require a tight seal without the use of any additional adhesives or coatings. This feature is quite vital in food packaging, where freshness of the packed product is an important factor. The film provides good seals at relatively low temperatures, thereby being advantageous for high-speed packaging lines.

Food Packaging: CPP film is also used in the food industry for the sealing of bags and pouches filled with anything from snacks to frozen foods. It assists in packaging heat-sensitive products due to its low-temperature heat sealability, ensuring that the nutritious value of the food remains intact. The clarity of CPP film enables clear visibility of the product inside, another major marketing and sales advantage.

Sterilization and Retort Packaging: CPP films, primarily those developed for retort applications, such as RCPP (Retort CPP), withstand the high temperature applied during sterilization procedures. As such, they are suitable for packaging ready-to-eat meals, sauces, and other products that require heat treatment for safety and a longer shelf life.

Manufacturing of Bags Using CPP Film

The flexibility and strength of CPP film make it suitable to make the following types of bags:

Stand-up pouches are one of the most important usages for CPP films due to their perfect thickness and strength. Stand-up pouches, for products like pet foods, snacks, and condiments, are one of the most in-demand packaging applications today. In fact, such pouches take great advantage of its providing a strong bottom combined with sealing characteristics on both front and rear panels.

Twist Wraps: CPP film is used in confectionery for making twist wraps for candies and chocolates. The softness and the facility of sealing of the film allow quick packaging and add to the aesthetic appeal and functionality of the product.

Specialty Bags: CPP films can also be used in the making of bags for garments, flowers, and other items wherein the looks are as much significant as functionality will be. The film can be embossed or printed for premium appearance without sacrificing protection.

Other Innovative Uses of CPP Film

Beyond traditional packaging, properties of CPP film enable a variety of innovative applications:

Lamination: CPP films are very often used as sealant layers in laminated structures, usually in combination with BOPP or metallized films to improve barrier properties against moisture, oxygen, and light. This is very important in pharmaceutical packaging where the integrity of the product over time is very important.

Labeling: CPP film is used in labeling due to its clarity, durability, and good printability, especially in environments where the label needs to go through moisture and temperature changes. Its use in both pressure-sensitive labels and shrink labels adds flexibility to the branding.

Industrial Packaging: CPP films for industrial purposes find their application in the covering of sensitive components of machinery during transport. Its toughness, more specifically puncture resistance, is useful in packaging electronic parts or mechanical parts where protection against physical damage is highly required.

Medical and Hygiene Products: CPP films find a place in the medical field in packaging medical tapes, plasters, sterile packaging, among others, where clarity imparts better visibility of the contents within, and sealing properties retain the contents sterile.

Technical Advantages and Considerations

Flexibility and softness: compared to BOPP, CPP is softer and more pliable. Thus, CPP applies to the packaging of products that require a soft touch or when films need to take the shape of irregular forms.

Recyclability: one of the ecological friends' advantages of CPP is the ability for recycling. At the moment when industries are being oriented towards ecology, the recyclability of CPP for the production of new packaging material is a big plus.

Personalization: In addition, the actual films of CPP may be changed in thickness and barrier properties by adding layers, or additives for anti-fog or UV resistance.

Disadvantages: While CPP has the above advantages, it needs to mention some limitations: some competitors offer better barrier properties, such as BOPP or PET; at extremely low temperatures, the material turns brittle unless it has been said otherwise, in formula. The end

CPP film's sealing, bag making, and other usages show it as indispensable to modern packaging. The clarity-sealing-flexible combination makes this film a vital material for industries seeking functionality with aesthetic appeal. With continuous research and development, CPP film is continuously getting updated, providing new solutions for packaging challenges with consideration for sustainability. With customer requirements developing consistently in a more complex way, CPP films have the flexibility to lead in package innovation.

În termen de 15-20 de zile de la primirea plății...more